Sliding doors

I-Process sliding doorsérie 6700

THE MINIMAL SLIDING SYSTEM FOR LARGE PROJECTS

The new 6700 I-Process aluminium sliding window offers an industrial vision of joinery.

A variation of the Confort+ sliding window (link to Comfort+ page), the I-Process sliding window has been designed to optimise the production of volumes and thus meet the needs of large-scale projects.

Sepalumic

I-Process sliding door 6700

Thanks to its harmonious interior and exterior design, its high insulation performance and its optimal level of safety, this sliding window provides a turnkey solution for the projects of builders of individual houses, collective housing and commercial buildings. Ideal for bathing the interiors of flats in light thanks to its ever thinner aluminium profiles: 3cm central jamb, 5cm side opening.

Combined with Sepalumic’s 5700 windows and 4700 entrance door, you have a complete range of joinery that matches the building’s façade.

Optimised production for professionals

The I-Process sliding window meets the main expectations of the end-users in terms of clear glazing, insulation and security. However, it is not less productive. Most of the accessories that contribute to better technical performance are integrated into the structure. There are no additional elements to be cut out, nor are there any additional profiles, which considerably reduces the manufacturing time.

Design MINIMAL

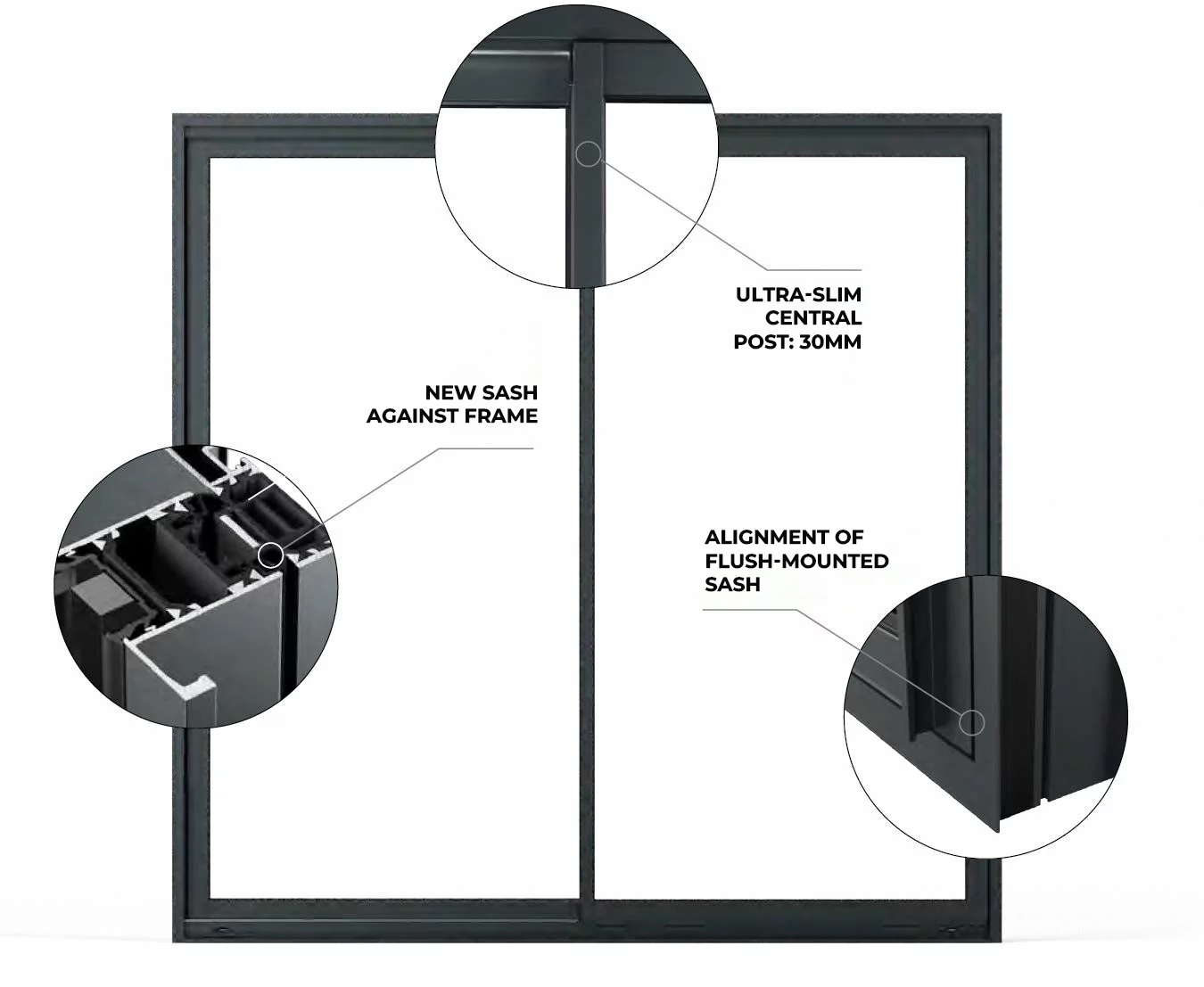

The I-Process sliding window combines new profiles and new accessories developed specifically to minimise the visible surfaces and thus increase the luminosity inside the house.

- Central jamb: 30mm

- Sash bars: 55 mm

- Head jambs: 51mm

Unique aesthetic signature :

- Flush sash and frame, flatness and homogeneity of the profiles

- Head jamb reinforcement: angular and ergonomic design

- Water drainage system: concealed drains and invisible nozzle

Manufacturing

Developed for industrial manufacturing, it is therefore the best “aesthetic/performance/productivity” ratio.

- Optimisation of the references of the 70 range: skirtings, flaps, joint covers and raceways.

- Pre-assembled heat shields and sealing elements.

OPTIMISED MACHINING

Types of machining :

- Traditional punches.

- Industrial punches.

- Optimisation for production on a machining flow line.

Performance

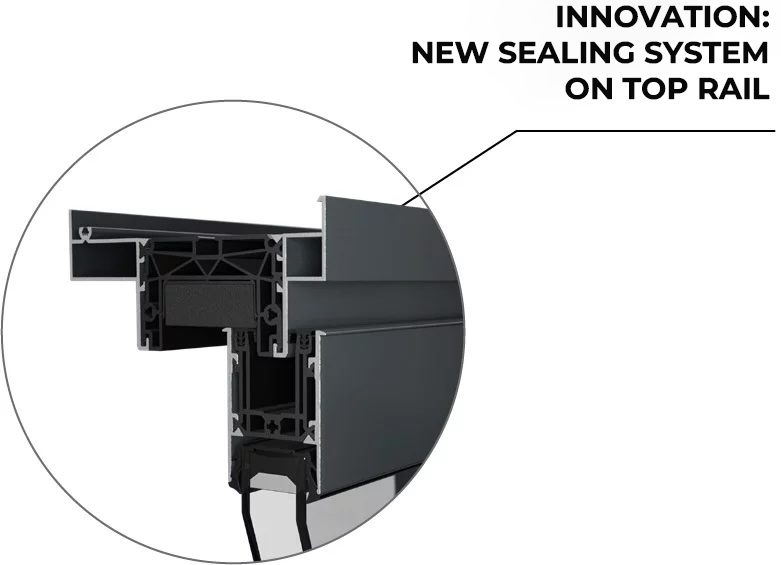

With slim profiles for better light transmission, optimised thermal breaks and new patented sealing accessories, this sliding system has been entirely designed to ensure maximum interior comfort.

- Thermal insulation up to 1.3 in Uw, thanks to innovative thermal breaks.

- Unprecedented A*4 / E*7B tightness level.

CONTROLLED BIMETAL EFFECTS

The ultra-thin head jambs combined with the new locks and strikers keep the frame functional under the bimetal effect.

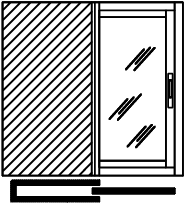

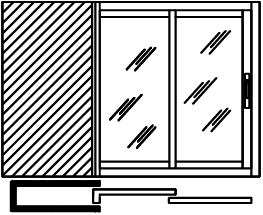

Possible configurations

2 rails up to

4 leaf

up to 6 leaf

1 track up to

2 leaf

2 tracks up to

4 leaf

Technical information and performances

Technical Informations

Dim. max/VTL : 1375mmx2500mm

Weight : 200kg

Model performance

Thermal : Uw/m².K = 1,3 - Sw = = 0,34 - TLw = 0,67 Ug/m².K = 1.0

Sealing : A*4 E*6B V*A2

PMR : With thermal break